October 7, 2021

Welcome to our Monday Minute Interview Series

In this series, Christopher Candy, VP, Business Development at Mobilizz™ sits down with the people and businesses of the Telematics industry. This week we caught up with:

Nick Giampaolo

Nick Giampaolo is the owner of Metalogics and has been in the scrap metal industry since graduating from the University of Western Ontario in 2007.

Metalogics buys and sells scrap metal. We provide customized scrap metal and recycling services to meet the needs of residential, commercial, and industrial scrap metal producers. We are committed to streamlining this process to build stronger relationships with our customers. We do this through the quality of our service, integral pricing, and, most importantly, customer care. We model our business to supply what our customers want and expect—great service and great prices.

Chris and Nick discuss how integrating multiple telematics components in his company has increased revenues and decreased operating costs by using a top-down, data-driven approach. Metalogics is a Mobilizz™ customer.

What does Metalogics do?

Metalogics is a scrap metal recycling company. We purchase and sell scrap metal based on chemistry and density to local mills.

How are you using telematics in your business?

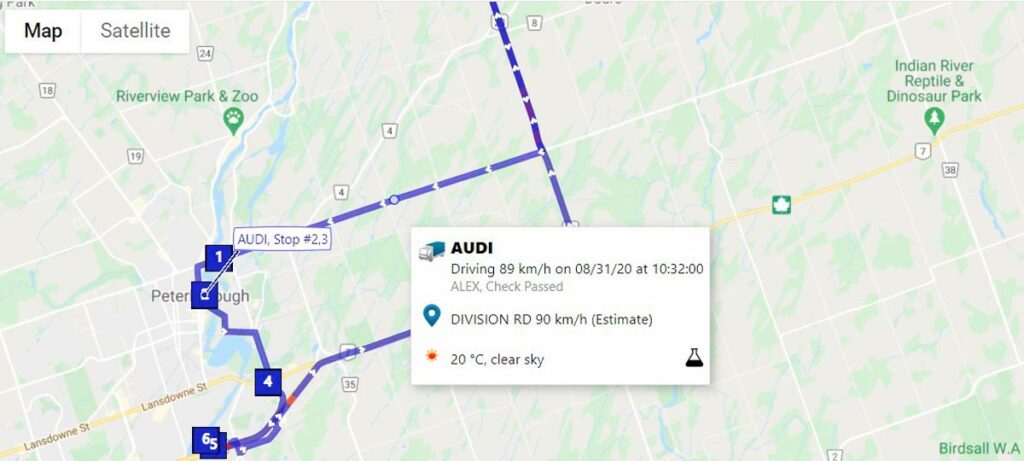

Telematics is giving us detailed data driven results. What this means is the ability to analyze our entire business: costs, time, run sheets, return on assets as well as the efficiency of our labour and assets.

And has it helped?

It has definitely helped! There are so many things we thought we were aware of, but until the data is in front of you, you never know the true cost of your operations.

As an example, a frequent customer run that we assumed had a 2-hour completion turnaround actually turned out to be closer to 2.5-hours (25% more than initially thought). This means we had been undercutting ourselves for the entire life of that customer. That time and lost revenue adds up fast.

What approach did you take to bringing on telematics?

We took a top-down approach, starting with the overall business and not just our fleet. First, we identified what processes we could partially or fully automate. Then, found out where we could find time savings by going digital, and what data was needed to truly understand our costs. Finally, we determined what we needed to do to become more competitive and better serve our customers.

This ultimately led us to telematics as a solution, and the systems that integrate with it.

Aside from telematics, what other systems have you implemented?

After we added telematics to our systems, we implemented ELD (Electronic Logging Devices) for our drivers. Then, we added Bluetooth trackers to all our scrap metal bins in order to monitor their location and time at a customer site. Finally, we added in ProntoForms to go completely paperless in the field.

What has been the biggest surprise because of all of these new systems and processes put in place?

The biggest surprise has been uncovering the true hidden costs of operating our business, as well as providing accurate information – what we thought we knew versus what was actually happening. For example, we were quickly able to take how long we thought a call to a customer would be and compare it to the actual timeline. This has saved us a lot of money while at the same time made us much more competitive.

We also realized how quickly our new systems are at allowing us to adapt and make changes because of real-time business data being collected. When COVID hit and the roads were empty, our drive times to certain customers dropped significantly. We were able to use that data to adjust our pricing in the customer’s favour pretty much overnight.

How do these new systems give you an advantage over the competition?

We are in an industry where the product delivered is essentially the same: my piece of steel is the same as someone else’s, so we have to compete on price. Getting as close as possible to knowing our true cost will give us a big advantage when going to price a customer. The systems are also critical in helping us make better informed decisions, such as whether we want to keep servicing a customer or not.

How has all of this improved your business?

We are no longer making subjective decisions anymore.

Therefore we are able to run a true P&L on our assets. Prior to telematics, we were manually tracking [scrap metal] bins. Data always got lost and we wouldn’t know how long bins were sitting at a location for. That means we had no idea if we were losing or making money on our bins.

On top of that, when we need to purchase more bins, the question has always been: “how many bins do we need to order?” There was never a data driven answer to that.

Now we know exactly how many days or months a bin turns over at a customer. This allows us to easily identify the customers that we may need to get rid of and reallocate those bins. We not only earn more on our assets, but when it comes time for procurement, we now know exactly how many we need – we may only need 5 bins instead of 30. At $10,000 per bin, that is a lot of money saved on what used to be an arbitrary decision process.

What has been the biggest efficiency gain you found?

Going paperless has been incredible. We added Geotab Drive for ELD (Hours of Service and Pre-Trip inspections) which has saved both our back office and drivers a significant amount of time.

We also added ProntoForms to replace our paper Bill of Lading forms, saving on average 5 minutes per call (customer visit). This efficiency has saved us a half service day to our work week, per truck!

Lost paperwork was always an issue – particularly as it adds time to our invoicing process. Now, once the driver hits “send” on the Bill of Lading, paperwork is digitally sent to various internal departments, as well as to the customer. This means our invoices go out much, much faster, and eliminates disputes related to lost paperwork.

Any tips for anyone looking to add telematics to their business?

My biggest suggestion would be to get the most training possible on the system so you can best mine and use the data you are collecting. Training is key in order to decipher and analyze the data immediately.

Where do you see your industry going in the next 5 years?

It is going to continue to get more competitive. Things are moving to a more corporate-style structure. The barriers to entry are shrinking and it is a race to the bottom in terms of prices and margins. That means you need to be as calculated as possible to offer the most competitive price. You can’t make subjective decisions anymore, they absolutely need to be data driven. We can do exactly that with telematics and with what Mobilizz has shown us.